Valentine's Sale ends in

Metal Building Gauge Guide

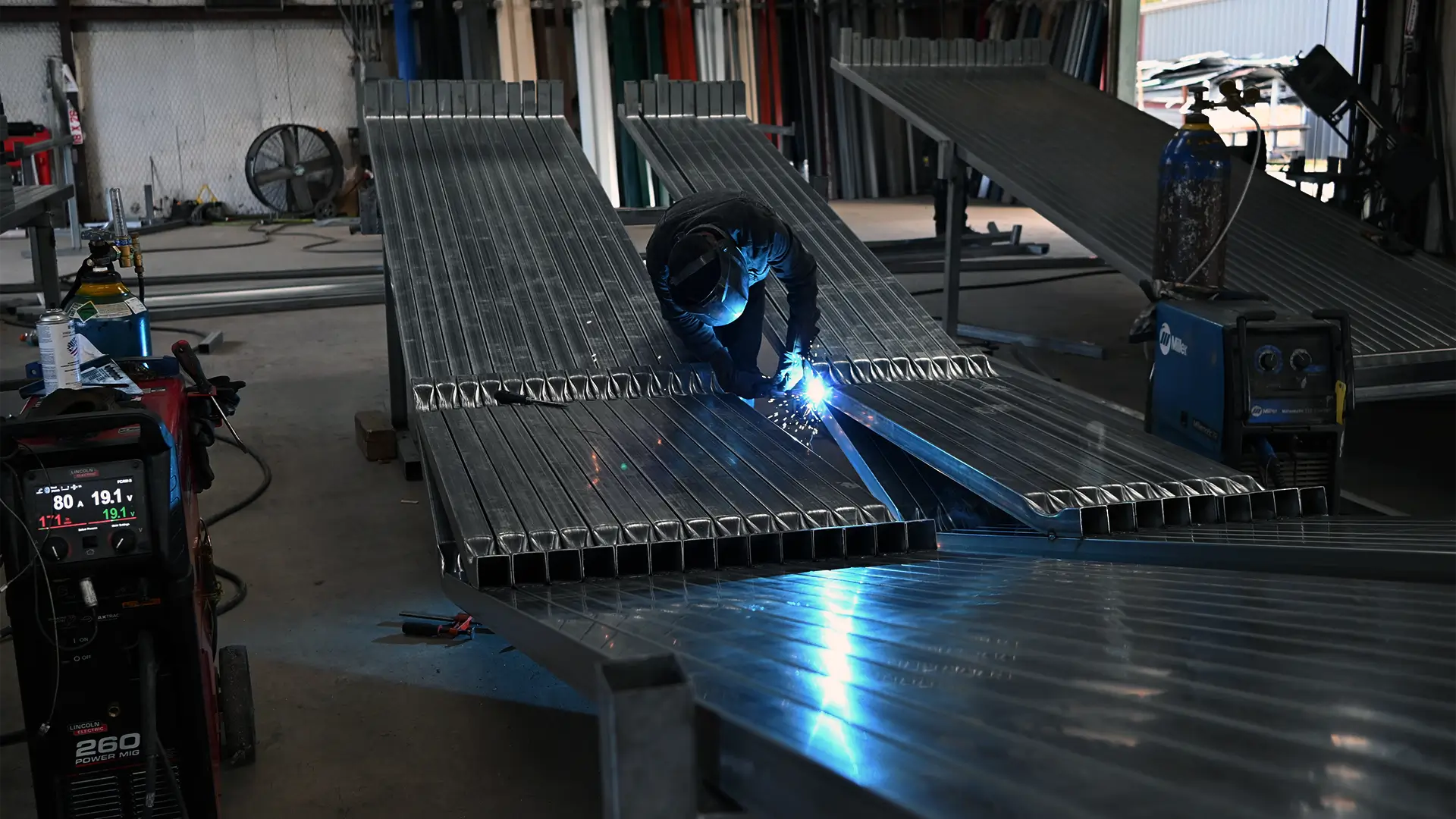

Understanding metal building gauge is crucial when investing in steel carports, garage, or custom metal structures. The steel gauge you select directly impacts your building's strength, durability, and performance against harsh weather conditions.

This comprehensive guide explores everything you need to know about metal building gauge, from basic measurements to advanced selection strategies. Whether you're planning a residential carport or commercial facility, choosing the correct steel thickness ensures optimal performance and longevity.

What Is Metal Building Gauge?

Metal building gauge refers to the thickness measurement of steel used in construction. The gauge system might seem counterintuitive—lower numbers indicate thicker steel materials.

For example, a 26-gauge panel is thicker than a 29-gauge panel. Similarly, 12-gauge framing is thicker than 14-gauge framing. This steel gauge standard applies across the entire steel construction industry.

Understanding metal thickness helps you make informed decisions about your project's structural integrity and cost-effectiveness.

Why Metal Building Gauge Matters

The steel gauge you choose affects multiple aspects of your structure:

- Structural strength and stability

- Wind resistance capabilities

- Long-term durability

- Installation requirements

- Overall project costs

Selecting the appropriate metal thickness ensures your investment performs optimally for decades. Different applications require different steel specifications based on environmental conditions and structural demands.

29-Gauge Panels: The Standard Metal Building Gauge Choice

29-gauge panels represent the most common steel thickness for residential and light commercial applications. This panel gauge offers excellent value while meeting most structural requirements.

Benefits of 29-Gauge Steel Panels:

Proven reliability across thousands of installations makes this metal gauge a trusted choice. The lightweight nature of this steel thickness simplifies installation processes and reduces labor costs.

Cost-effective performance is a key advantage of this panel gauge. When properly engineered with adequate bracing, this metal thickness withstands normal weather conditions effectively.

Versatile applications make this steel gauge suitable for standard carports, garage, and utility buildings. Most building codes accept this panel thickness for residential structures.

Performance Characteristics

This metal building gauge provides adequate protection against sun, rain, and everyday wear. The steel thickness performs well in moderate climate conditions with proper installation techniques.

Standard engineering practices optimize this panel gauge for maximum efficiency. Professional installers understand how to maximize this metal thickness performance through proper bracing and anchoring systems.

26-Gauge Panels: Premium Metal Building Gauge Option

26-gauge panels offer superior performance when standard steel thickness isn't sufficient. This upgraded metal gauge provides enhanced rigidity and weather resistance.

Advantages of 26-Gauge Steel Panels:

Increased thickness gives this panel gauge superior dent resistance and structural integrity. The enhanced metal thickness reduces flexing and maintains panel flatness over time.

Superior wind resistance makes this steel gauge ideal for storm-prone regions. Higher uplift ratings characterize this panel thickness compared to thinner alternatives.

Reduced oil canning is a significant benefit of this metal building gauge. The thicker material maintains its appearance better than standard steel thickness options.

When to Choose 26-Gauge Steel

High-wind areas benefit significantly from this panel gauge. Coastal regions and tornado-prone zones require this enhanced metal thickness for optimal safety.

Large roof spans perform better with this steel gauge. The increased rigidity of this panel thickness prevents sagging and maintains structural integrity.

Long-term durability is enhanced with this metal building gauge. Premium applications justify the investment in this superior steel thickness.

14-Gauge Framing: Industry Standard Metal Building Gauge

14-gauge steel tubing represents the most common frame thickness for structural framing. This framing gauge has proven its reliability across countless installations.

14-Gauge Frame Benefits:

Proven track record makes this steel thickness a reliable choice for standard applications. The frame gauge meets most residential and light commercial requirements.

Cost-effective strength characterizes this metal thickness. The balance between performance and affordability makes this framing gauge extremely popular.

Versatile compatibility allows this steel gauge to work with various panel thicknesses. Both 29-gauge and 26-gauge panels pair well with this frame thickness.

Engineering Capabilities

This metal building gauge can be certified for specific wind and snow load ratings. Professional engineers calculate load capacities for this framing gauge based on local requirements.

Anchor systems optimize this steel thickness performance. Proper foundation connections maximize this frame gauge structural capabilities.

12-Gauge Framing: Heavy-Duty Metal Building Gauge

12-gauge steel tubing provides maximum strength in frame thickness options. This premium framing gauge handles the most demanding applications.

12-Gauge Frame Advantages:

Maximum strength defines this steel thickness. The thicker material resists bending and deformation under extreme conditions.

Higher wind ratings are achievable with this metal building gauge. Storm-prone areas benefit from this enhanced frame thickness performance.

commercial applications often require this framing gauge. Large spans and tall structures benefit from this robust steel thickness.

Applications for 12-Gauge Steel

Wide-span buildings need this frame thickness for structural integrity. The enhanced dimensions of this metal gauge support larger unsupported spans.

Tall structures benefit from this framing gauge. RV covers and commercial often specify this steel thickness for maximum stability.

Extreme weather zones require this metal building gauge. Hurricane-prone areas and high-wind regions depend on this superior frame thickness.

Steel Gauge Selection Factors

Choosing the right metal thickness involves multiple considerations. Your steel gauge decision affects performance, cost, and longevity.

Climate Considerations

Wind speeds in your area influence panel gauge selection. Higher wind zones require upgraded steel thickness specifications.

Weather patterns affect metal building gauge performance. Severe weather areas benefit from enhanced frame thickness options.

Environmental exposure impacts steel durability. Coastal areas need superior metal thickness for salt air resistance.

Structural Requirements

Building size influences steel gauge needs. Larger structures require heavier frame thickness specifications.

Span distances affect panel gauge selection. Wider spans need thicker metal building gauge for adequate support.

Height considerations impact steel thickness choices. Taller buildings benefit from enhanced frame gauge strength.

Economic Factors

Initial investment varies with metal thickness selection. Premium steel gauge options cost more upfront but provide better long-term value.

Long-term costs favor quality panel gauge choices. Durable frame thickness options reduce maintenance and replacement expenses.

Insurance considerations may favor upgraded steel thickness. Some policies offer discounts for enhanced metal building gauge specifications.

Steel Gauge Combinations

Combining different metal thickness options optimizes performance and cost. Strategic steel gauge selection maximizes your investment.

Standard Steel Combinations:

29-gauge panels with 14-gauge framing provides excellent value for most applications. This metal thickness combination suits standard residential needs.

26-gauge panels with 14-gauge framing offers enhanced panel performance with standard framing. This steel gauge combination works well for moderate upgrade needs.

29-gauge panels with 12-gauge framing prioritizes structural strength over panel thickness. This frame gauge combination suits specific engineering requirements.

26-gauge panels with 12-gauge framing delivers maximum performance in both categories. This premium metal building gauge combination handles the most demanding applications.

For detailed steel construction standards, the American Institute of Steel Construction provides comprehensive guidelines for optimal steel thickness selection.

Installation Considerations for Steel Gauge

Proper installation maximizes any metal thickness performance. Understanding steel gauge installation requirements ensures optimal results.

Foundation Requirements

Anchor systems must match frame thickness specifications. Heavier steel gauge options require stronger anchoring systems.

Foundation design should complement metal thickness selection. Professional engineers specify foundations for specific steel gauge combinations.

Soil conditions affect panel gauge installation requirements. Local soil types influence frame thickness anchoring needs.

Bracing Systems

Proper bracing optimizes steel thickness performance. Strategic bracing maximizes any metal building gauge structural capabilities.

Engineering calculations determine frame gauge bracing requirements. Professional designs ensure adequate steel thickness support.

Installation techniques affect panel gauge performance. Proper procedures maximize metal thickness effectiveness.

The Metal Building Manufacturers Association offers industry best practices for steel gauge installation and performance standards.

Regional Steel Requirements

Different regions have varying metal thickness requirements. Local conditions influence optimal steel gauge selection.

Hurricane-Prone Areas

Coastal regions often require enhanced frame thickness specifications. Hurricane conditions demand superior metal building gauge performance.

Building codes may mandate specific steel gauge requirements. Local regulations influence panel thickness selection options.

Insurance requirements sometimes specify frame gauge minimums. Policy terms may require upgraded steel thickness options.

Tornado Zones

High-wind areas benefit from upgraded metal thickness specifications. Tornado-prone regions need enhanced steel gauge performance.

Storm shelters require specific frame thickness standards. Safety applications demand premium panel gauge options.

Emergency ratings may specify steel thickness requirements. Disaster-resistant structures need superior metal building gauge specifications.

Quality Assurance in Steel Construction

Ensuring proper steel gauge quality protects your investment. Quality control measures verify metal thickness specifications.

Manufacturing Standards

Steel quality affects frame gauge performance. Premium steel sources ensure consistent panel thickness properties.

Coating systems protect metal building gauge materials. Quality finishes extend steel thickness lifespan significantly.

Quality control processes verify frame gauge specifications. Reputable manufacturers maintain strict metal thickness standards.

Certification Programs

Engineering certifications validate steel gauge performance. Professional stamps ensure panel thickness compliance with local codes.

Testing standards verify frame thickness capabilities. Laboratory testing confirms metal building gauge specifications.

Warranty programs back quality steel gauge products. Manufacturer guarantees protect metal thickness investments.

Cost Analysis of Steel Options

Understanding metal thickness costs helps optimize your investment. Steel gauge pricing varies based on thickness and quality.

Initial Investment Considerations

Material costs increase with frame gauge thickness. Premium panel thickness options command higher prices.

Installation costs may vary with steel gauge selection. Some metal thickness options require specialized installation techniques.

Engineering costs might increase with frame gauge complexity. Custom steel thickness applications need professional design services.

Long-Term Value Proposition

Durability benefits justify metal building gauge investments. Quality panel thickness options last longer and perform better.

Maintenance savings result from proper steel gauge selection. Durable frame thickness options reduce ongoing maintenance costs.

Resale value benefits from quality metal thickness choices. Premium steel gauge buildings maintain value better over time.

Professional Steel Consultation

Working with metal thickness experts ensures optimal selection. Professional guidance maximizes steel gauge performance and value.

Design Services

Engineering expertise optimizes frame gauge selection. Professional engineers understand panel thickness requirements for specific applications.

Custom solutions accommodate unique steel thickness needs. Specialized applications may require custom metal building gauge specifications.

Code compliance ensures proper frame gauge selection. Professional services guarantee steel thickness compliance with local requirements.

Installation Services

Professional installation maximizes metal thickness performance. Experienced installers understand steel gauge requirements and techniques.

Quality assurance programs verify panel gauge installation. Professional services ensure proper frame thickness installation procedures.

Warranty support backs professional steel gauge services. Reputable installers guarantee metal thickness installation quality.

The International Building Code provides standardized requirements for steel gauge specifications across different regions and applications.

Conclusion: Making the Right Steel Choice

Selecting the appropriate metal building gauge is crucial for your project's success. The right steel thickness ensures optimal performance, durability, and value.

Consider your specific needs when choosing panel gauge options. Climate conditions, structural requirements, and budget constraints all influence frame thickness selection.

Professional consultation helps optimize steel gauge choices. Expert guidance ensures your metal thickness selection meets all requirements while maximizing value.

Quality steel options provide superior long-term performance. Investing in appropriate panel gauge specifications protects your investment and ensures decades of reliable service.

Remember that frame thickness is just one factor in overall building performance. Proper design, installation, and maintenance all contribute to maximizing your steel gauge investment.