Valentine's Sale ends in

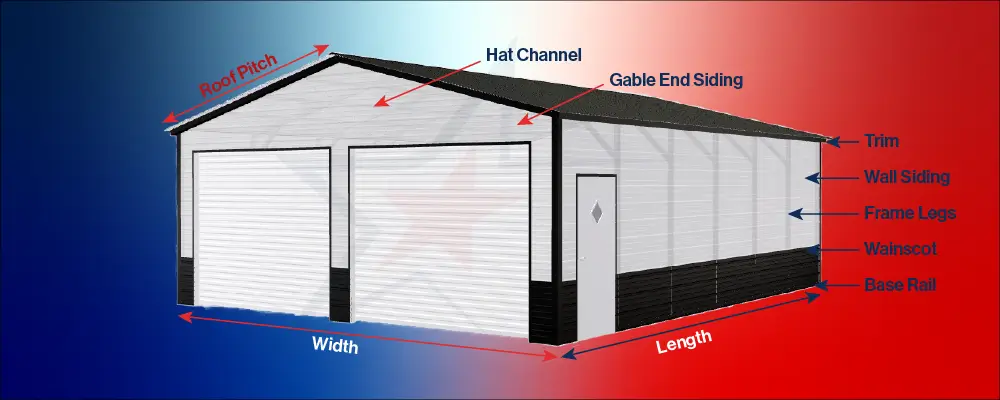

Understanding Building Components

When it comes to constructing a durable, weather-resistant, and aesthetically pleasing metal garage, understanding each component's role is crucial for both builders and property owners. Modern metal garages have evolved far beyond simple storage structures, becoming sophisticated buildings that combine functionality, durability, and attractive design elements. This comprehensive guide examines every critical component of metal garage construction, from the foundational base rail to the protective roof pitch, providing you with the knowledge needed to make informed decisions about your next building project.

The Foundation of Excellence: Base Rail System

The base rail serves as the cornerstone of any well-constructed metal garage, functioning as the foundation support structure that provides stability for the entire garage frame. This critical component acts as the interface between your concrete foundation or gravel pad and the vertical frame legs, distributing the building's weight evenly across the foundation surface.

Modern base rail systems are typically constructed from heavy-gauge galvanized steel, engineered to resist corrosion and provide decades of reliable service. The design incorporates pre-drilled mounting holes that align perfectly with standard concrete anchor systems, ensuring a secure connection that can withstand significant wind loads and seismic forces. The rail's profile is specifically designed to channel water away from the building's interior, incorporating subtle drainage features that prevent moisture accumulation at the foundation level.

The installation process for base rails requires precise measurement and leveling, as any irregularities at this stage will compound throughout the entire structure. Professional installers use laser levels and string lines to ensure perfect alignment, understanding that a properly installed base rail system is essential for the garage's long-term structural integrity. The rails are typically secured using heavy-duty concrete anchors or through-bolts, with spacing determined by local building codes and wind load requirements.

Vertical Strength: Frame Legs and Structural Support

Frame legs represent the vertical backbone of metal garage construction, serving as the primary load-bearing elements that transfer roof loads down to the foundation system. These vertical support posts are engineered to provide structural stability for the garage frame while accommodating the thermal expansion and contraction that occurs with temperature changes.

Contemporary frame leg designs utilize high-strength steel tubing or C-channel profiles, selected based on the building's dimensions, local snow loads, and wind requirements. The legs are typically spaced at regular intervals, commonly 8 to 12 feet on center, with closer spacing required in areas subject to high wind or snow loads. Each leg is precisely cut to length and features connection points for horizontal girts, roof purlins, and wall panels.

The connection between frame legs and the base rail system utilizes heavy-duty bolted connections, often incorporating adjustable base plates that allow for minor field adjustments during installation. This connection method provides superior strength compared to welded alternatives while allowing for easier transportation and assembly. The upper ends of frame legs connect to the roof structure through engineered brackets or direct welding, depending on the specific building design and manufacturer specifications.

Advanced frame leg systems incorporate features such as reinforced connection points, integrated cable management systems for electrical installations, and provisions for overhead door hardware. Some manufacturers offer frame legs with built-in leveling systems that compensate for minor foundation irregularities, ensuring a perfectly plumb structure regardless of small variations in the concrete pad.

Weather Protection: Wall Siding Systems

Wall siding serves as the primary weather barrier for metal garages, providing protection against rain, wind, snow, and UV radiation while contributing significantly to the building's structural integrity. Modern wall siding systems are engineered to work in conjunction with the frame structure, adding shear strength that helps the building resist lateral forces.

The most common wall siding profiles include ribbed panels, standing seam systems, and architectural profiles that mimic traditional building materials. Ribbed panels, featuring alternating raised and recessed sections, provide excellent strength-to-weight ratios while creating attractive shadow lines that enhance the building's visual appeal. The ribs also serve as structural elements, allowing the panels to span greater distances between support points.

Installation of wall siding requires careful attention to proper overlap, fastener placement, and weather sealing. Panels are typically installed from bottom to top, with each successive course overlapping the previous by a specified amount to ensure weather tightness. Side laps between adjacent panels incorporate sealant or tape systems that prevent water infiltration while allowing for thermal movement.

Modern wall siding incorporates advanced coating systems that provide superior corrosion resistance and color retention. Galvanized steel substrates are typically coated with multi-layer paint systems that include primer, color coat, and clear protective finishes. These coating systems are designed to withstand decades of exposure to harsh weather conditions while maintaining their appearance and protective properties.

Foundation and Visual Enhancement: Wainscot Systems

Wainscot panels provide both functional and aesthetic benefits to metal garage construction, serving as lower decorative wall panels that offer additional protection and visual appeal. These panels are typically installed in the lower portion of the wall system, extending from the base rail to a height of 3 to 4 feet above the floor level.

The functional benefits of wainscot systems include protection of the lower wall area from mechanical damage, improved moisture resistance at the foundation level, and enhanced structural performance through increased wall thickness. The wainscot panels are often constructed from heavier gauge materials than the upper wall panels, providing superior resistance to impact damage from equipment, vehicles, and general use.

From an aesthetic standpoint, wainscot systems create visual interest through color contrast, texture variation, or profile differences. Many property owners choose complementary colors that enhance the overall building appearance while providing a traditional architectural element that connects the structure to surrounding buildings or landscape features.

Installation of wainscot systems requires coordination with the main wall siding installation, ensuring proper overlap and weather sealing at the transition zone. The top edge of the wainscot typically incorporates a flashing system that directs water away from the joint, preventing moisture infiltration that could lead to corrosion or other problems.

Architectural Finishing: Trim and Edge Details

Trim components provide the finishing touches that transform a functional metal building into an attractive architectural element. These decorative edge finishing elements deliver a clean, professional appearance while serving important functional roles in weather protection and structural completion.

Corner trim pieces cover the vertical joints where wall panels meet at building corners, providing weather sealing while creating clean, finished edges. These components are typically formed from the same materials as the wall panels, ensuring color matching and consistent performance characteristics. The trim pieces incorporate overlapping flanges that direct water away from the joint while accommodating thermal movement.

Door and window trim components frame these openings while providing essential weather sealing and structural support. The trim pieces must accommodate the movement of doors and windows while maintaining effective seals against water and air infiltration. Many trim systems incorporate removable components that allow for future maintenance or replacement of doors and windows without disturbing the surrounding wall system.

Rake trim and fascia boards complete the roof edge details, providing weather protection for the roof structure while creating finished edges that enhance the building's appearance. These components must be carefully designed to handle wind uplift forces while directing water into the gutter system or away from the foundation.

Structural Completion: Gable End Siding

Gable end siding represents the triangular wall sections that close off the ends of gabled roof buildings, requiring specialized design considerations to accommodate the sloping roof lines while maintaining weather protection and structural integrity. These components must interface seamlessly with both the vertical wall systems and the roof structure.

The design of gable end siding involves complex geometric calculations to ensure proper fit and weather sealing at all intersection points. The panels must be precisely cut to follow the roof slope while maintaining adequate overlap with adjacent components. Special attention is required at the peak where panels from opposite sides meet, typically requiring custom trim pieces or specialized closure systems.

Installation of gable end siding requires careful coordination between the roofing and wall installation teams, as these components often must be installed simultaneously with roof panels to achieve proper weather sealing. The process typically involves installation of a temporary support system to hold the panels in position while roof components are installed and secured.

Modern gable end systems often incorporate ventilation features that promote air circulation within the building while preventing weather infiltration. These ventilation systems may include ridge vents, soffit vents, or specialized louver systems that provide controlled air exchange.

Crown of Protection: Hat Channel and Ridge Systems

The hat channel, also known as the roof ridge cap, covers the peak joint where roof panels from opposite sides meet, preventing water infiltration while providing a finished appearance to the roof system. This component represents one of the most critical weather sealing elements of the entire building envelope.

Ridge cap systems must accommodate thermal movement of the roof panels while maintaining effective water sealing across a wide range of weather conditions. The design typically incorporates overlapping flanges that extend well down onto the roof panels, ensuring water cannot penetrate the joint even under severe weather conditions. Ventilation features may be incorporated to allow air circulation while preventing water entry.

Installation of ridge cap systems requires careful attention to end details, penetrations for vents or other equipment, and proper fastener placement. The caps are typically installed with concealed fasteners that penetrate only the underlying roof panels, avoiding punctures through the cap itself that could create leak points.

Advanced ridge cap systems may incorporate continuous ventilation features, snow retention systems, or provisions for solar panel mounting. These enhanced systems require coordination with other building components to ensure all performance requirements are met while maintaining the integrity of the weather barrier.

The Protective Shield: Roof Pitch and Panel Systems

Roof pitch represents the angled roof surface designed for proper water drainage and structural strength, serving as the primary weather protection element for the entire building. The selection of appropriate roof pitch involves balancing factors including local weather conditions, building codes, aesthetic preferences, and cost considerations.

Modern metal roofing systems offer numerous profile options, each designed to optimize performance for specific applications and conditions. Standing seam systems provide superior weather protection through concealed fasteners and continuous panel seams, while exposed fastener systems offer cost-effective solutions for many applications. The choice between systems depends on factors including building size, local weather conditions, and performance requirements.

Roof panel installation requires careful attention to panel layout, fastener placement, and weather sealing details. Panels must be properly aligned and secured to resist wind uplift while allowing for thermal movement. End laps between panels require sealant systems that maintain effectiveness over the building's service life.

Thermal performance of metal roofing systems has improved dramatically with the development of reflective coatings and insulation systems. Cool roof technologies reflect solar radiation while promoting rapid heat dissipation, reducing cooling loads and improving occupant comfort. Insulation systems may be integrated into the roof assembly or installed as separate components, depending on performance requirements and budget considerations.

Engineering Excellence: Structural Integration

The success of any metal garage construction project depends on the seamless integration of all components into a unified structural system. Each element must work in harmony with adjacent components while contributing to the overall performance of the building envelope. This integration requires careful engineering analysis and attention to detail during both design and construction phases.

Wind load resistance represents one of the primary design challenges for metal buildings, requiring coordination between the foundation system, frame structure, wall panels, and roof components. The building must be designed as a complete system that can transfer wind forces from the roof and walls down through the frame structure to the foundation. This load path must remain intact even under extreme weather conditions.

Thermal performance requires coordination between insulation systems, vapor barriers, and ventilation components. The building envelope must control heat transfer while managing moisture movement to prevent condensation problems. This balance is achieved through careful selection of materials and attention to detail at all connection points.

Seismic design considerations vary by geographic location but require attention to connection details and structural redundancy. The building frame must be capable of responding to ground motion while maintaining its integrity and protecting occupants and contents.

Quality Assurance and Long-Term Performance

The longevity and performance of metal garage construction depend heavily on quality control during manufacturing and installation, along with appropriate maintenance throughout the building's service life. Understanding these factors helps property owners make informed decisions and protect their investment.

Manufacturing quality control involves material selection, forming processes, coating application, and pre-installation inspection. Reputable manufacturers maintain strict quality standards and provide warranties that reflect confidence in their products. Steel substrates must meet specified strength and corrosion resistance requirements, while coating systems must demonstrate durability and color retention properties.

Installation quality significantly impacts long-term performance, making selection of experienced contractors essential. Proper installation requires understanding of structural requirements, weather sealing principles, and thermal performance considerations. Installers must follow manufacturer specifications while adapting to site-specific conditions and local building code requirements.

Maintenance requirements for metal buildings are generally minimal but should not be ignored. Regular inspection of fasteners, sealants, and coating systems helps identify potential problems before they become serious issues. Prompt attention to minor repairs prevents water infiltration that could lead to structural damage or costly remediation.

Future Considerations and Technological Advances

The metal building industry continues to evolve with advances in materials, manufacturing processes, and design techniques. Understanding these trends helps property owners make decisions that will remain relevant throughout their building's service life.

Sustainability considerations increasingly influence material selection and building design. Recycled content in steel products continues to increase, while manufacturing processes become more energy-efficient. Building designs incorporate features that improve energy performance and reduce environmental impact throughout the structure's lifecycle.

Smart building technologies offer opportunities for enhanced performance monitoring and automated control systems. Sensors can monitor structural performance, environmental conditions, and energy consumption, providing data that helps optimize building operation and maintenance schedules.

Advanced manufacturing techniques, including automated cutting and forming systems, improve precision while reducing costs. These technologies enable more complex designs and tighter tolerances, resulting in better fit and finish in the completed building.

Conclusion: Building for the Future

Metal garage construction represents a sophisticated blend of engineering, manufacturing, and construction expertise that delivers durable, attractive, and functional buildings. Understanding the role of each component helps property owners make informed decisions and communicate effectively with contractors and suppliers.

The integration of structural elements, weather protection systems, and aesthetic features requires careful planning and attention to detail throughout the design and construction process. When properly executed, metal garage construction delivers decades of reliable service with minimal maintenance requirements.

As technology continues to advance, metal buildings will incorporate new materials, improved manufacturing processes, and enhanced performance features. Property owners who understand these fundamentals will be better positioned to take advantage of these improvements while ensuring their buildings continue to meet their needs throughout their service life.

The investment in quality materials, professional installation, and appropriate maintenance will be rewarded with a building that provides excellent value and performance for many years to come. Whether used for vehicle storage, workshop space, or other applications, a well-constructed metal garage represents a wise investment in both functionality and property value.